Spotlight: Canon Solutions America

Spotlight: Canon Solutions America

On some level you’ve always known the secret to creating the best printed pieces possible, and that is this: Meet with your print service provider before you begin to design your piece.

That’s especially true when it comes to taking advantage of foiling and other embellishments when paired with the speed and flexibility of production inkjet printing, such as the Canon ProStream series or the Canon varioPrint iX from Canon Solutions America.

Not only can your print service provider show you how to use these finishing techniques to grab your audience’s attention, but they can also help you use them to protect your finished work from the knocks and scrapes encountered during shipping and beyond.

Dazzle Them With Foil

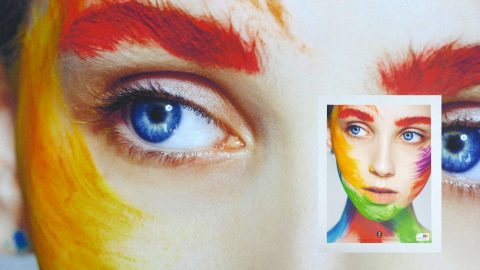

No other finishing technique boosts the perceived value of an item quite like the shimmer and shine of foil. And whether you choose old favorites like Silver or Gold foils or want to add a bit of vibrancy with colored – or even holographic – ones, the possibilities are endless.

Before you begin laying out your design file, though, you’ll want to run your plans by your printer, who can show you options you might not have considered before.

For example, instead of choosing hot foil stamping or cold foiling, you might go the digital foiling route instead.

Not only does digital foiling save you time and money by doing away with the need to create expensive dies, but it also gives you the ability to personalize every single piece in your print run using foil!

This effect – the finishing equivalent of “variable data printing” – is perfect if you’re producing a direct mailing, for instance, and want each recipient’s name rendered in glimmering foil. (Be sure to seek your printer’s help in setting up your files before you begin.)

Turn Heads With Specialty Coatings

Sure, you’re well aware of gloss and matte coatings, but did you know you can also add everything from sparkles to glow-in-the-dark effects to your inkjet-printed work, too?

There are also aqueous coatings that provide higher levels of gloss and more protection for your finished product. And that’s just the beginning!

You can apply any or all of these to specific areas on your piece (such as “Spot Gloss”) or you can flood the entire sheet with a single coating.

Again, consulting your print partner before you begin will save you big headaches later on, and will ensure you enjoy the best results possible.

Get Those Other Senses Involved

When it comes to packaging and other printed pieces, study after study has shown that engaging more than one of the senses dramatically increases the likelihood of a sale.

In addition to the finger-pleasing aspects of foil, you might consider adding the following to your inkjet-printed work:

- Embossing/Debossing. When you want a finishing technique that looks as good as it feels, these are hard to beat. Of course there’s more to a good emboss/deboss than a compelling die. Other factors your print provider will help you consider are the right paper for the job, the depth of impression, and even if nano-embossing or micro-embossing might be worth exploring. (Yes, these are a thing…and they are fabulous!)

- Tactile Coatings. Want to give your audience an experience they’ll never forget? Add a special texture to your piece that gives it the feeling of wood, leather, or something else entirely. Or go for that beloved favorite – a velvety, luxurious soft-touch coating.

- Scratch-and-Sniff Coatings. From home-baked cookies to that unmistakable new-car smell, if you can imagine a scent, chances are you can add it to your inkjet-printed creation. As you can imagine, this is when the help of an experienced print service provider really comes in handy.

Protect Your Vision…and the Environment

Coatings aren’t just for sensual appeal. Flooding a sheet with the right coating can make your final creation more robust and add a much-needed layer of protection between it and the scuffs and scrapes that print frequently suffers “in the wild.”

Yet this added protection needn’t come at the cost of the environment. The aqueous coatings frequently used do not interfere with the recyclability of your work. Hot and cold foils provide no barriers to recycling, either.

Remember, consulting your print provider about all your finishing options today means giving your clients your best work tomorrow.

Ready to see what a difference the right finishing techniques can make to your inkjet-printed projects? Enter to win 1 of 100 copies of Canon’s “Currents” direct mail promo right now! Hurry, this contest ends June 13, 2024. (North American entries only, please.) [THIS CONTEST IS NOW CLOSED]

As a reminder if you are a PRO member, you can get your copy for free in the PRO portal (click link below). Not a PRO member yet? What are you waiting for? Join the waitlist here.