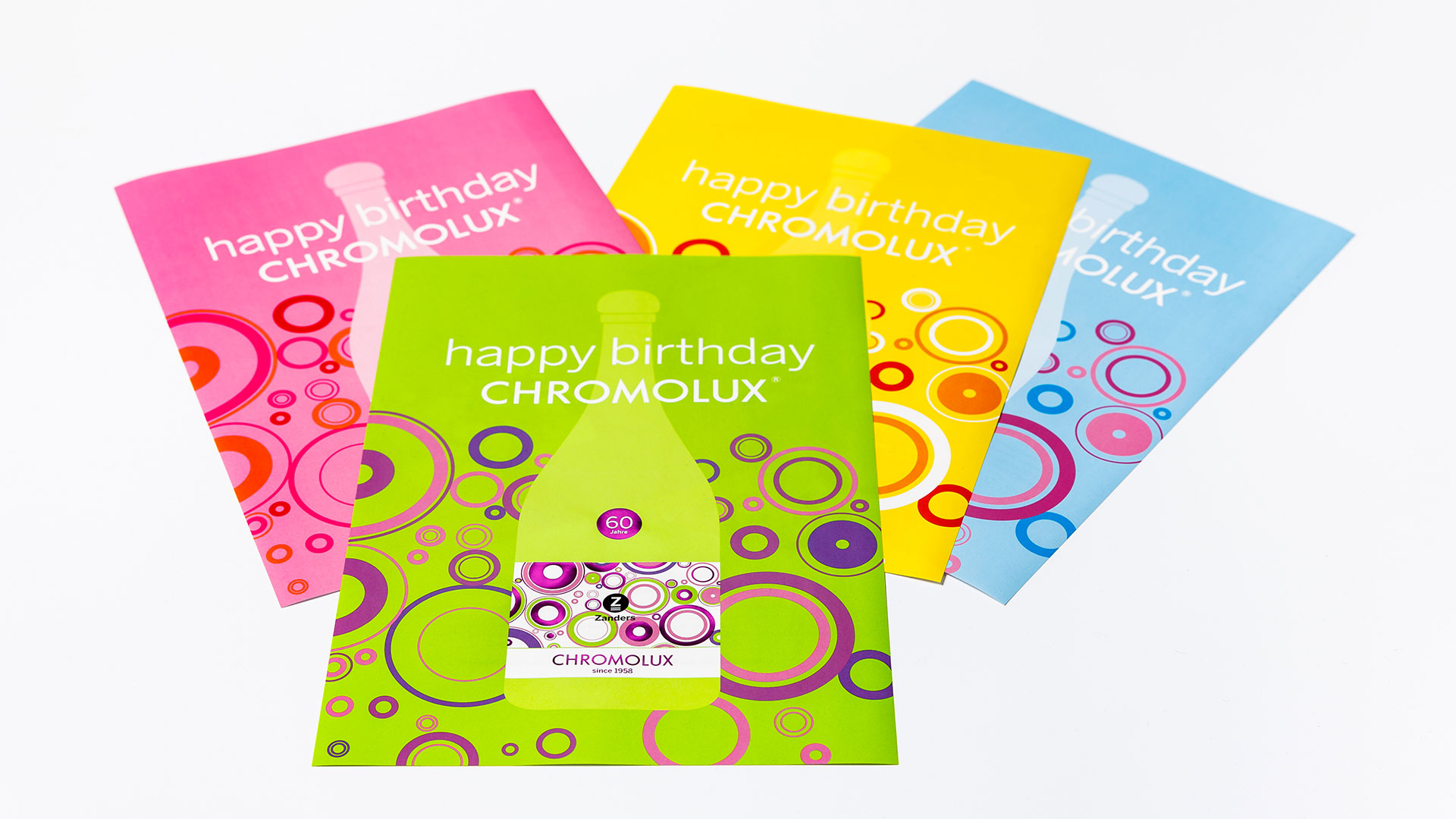

Spotlight: Zanders

For six decades now, designers who want their labeling, packaging and other premium creations to dazzle have insisted on Chromolux, the original one-side cast-coated (C1S), high-gloss sheet from Zanders. That’s because its unbeatable combination of super-smooth printing surface and superior graphic reproduction enables designers to craft pieces that literally outshine the competition.

How Can I Use Chromolux?

The Chromolux line has always been a source of inspiration for designers, brand owners and consumers. When it comes to designing packaging and labeling for high-end products and experiences, Chromolux gives you a competitive advantage every single time. That is due to its world-renowned, premium high gloss.

Both paper and board grades are available in a wide variety of subtle shades, including:

- High White

- Pearl

- Metallic Silver

- Metallized Aluminum

- Metallic Gold

- Additional colors (e.g., Black, Cream, Yellow, Red, Deep Blue).

In fact, you’ve probably seen it shimmering at you in department stores and elsewhere in a variety of forms.

Chromolux paperboard:

- Packaging for exclusive perfumes and cosmetics

- Exquisite confectionery packaging

- Calendars

- Covers

- Business cards

- Presentation folders

Chromolux C1S Labels:

- Champagne & spirits bottles

- Food & non-food containers

(The deliberately uncoated back has a functional treatment so that Chromolux paper has outstanding labeling properties!)

What Can I do with Chromolux?

The real question is what can’t you do with it? One of the most versatile premium papers on the market today, Chromolux can take virtually any finishing technique you throw at it with outstanding results, including:

- Embossing

- Hot- and cold-foil stamping

- Varnishing

- Die cutting

- Metallization

- Glitter lacquering

- Iriodin effects

- Flock printing

- Laser punching.

And now there is even Chromolux Digital – high-gloss, luxury sheets made especially for HP Indigo and dry toner digital printing presses.

The Secret of Chromolux’s Shine

At the heart of that incomparable shimmer and shine is a fantastic papermaking recipe that’s been passed down through the years.

Founded 189 years ago in Bergisch Gladbach, Germany, Zanders committed itself from the very beginning to producing quality papers by investing in the latest technologies.

In 1957, one of those technologies was Chromolux, which it began producing the following year. It’s made using the chrome cylinders of its cast-coating machines – the same ones it uses to this day! Here the combination of milk protein and marble powder creates that famous premium high gloss.

Compared to standard-coating, the chrome cylinders are about twice as hot, but apply relatively low pressure to the paper. The result: a superior gloss, the finest smoothness, and a high bulk – all of which make for outstanding printing, embossing and lamination.

Very quickly Chromolux became a best-selling sheet, its name now synonymous with cast-coated, high-gloss finished premium papers and boards.

Want to see for yourself how Chromolux has remained the No. 1 designer’s choice for high-gloss paper for 60 years and counting? [CLOSED] Enter to win one of 20 Chromolux mini-swatch decks from Zanders right now! Hurry, contest ends April 26th! (North American entries only, please.)