While there’s nothing wrong with printing on a white, coated sheet time after time, you’ll never know just how much more creative you could be if you don’t occasionally embrace colored paper.

Selecting a colored stock opens up new possibilities and allows for a different part of your creativity to flow. With the right knowledge, pushing this envelope allows for amazing design options.

In most cases, printing on a colored stock also means printing on an uncoated stock – metallic stocks are mica coated (a mineral consisting of shiny, transparent crystals) and thus fall into a different category – which means you are facing the challenge of dot gain, as well as the paper’s hue.

Depending on the color of the paper you choose, CMYK will have a dramatically different look. Printed on a cream stock, they have a warmer feel; printed on a paper with a blue or cool hue, the highlights of any image will be the color of the paper – reducing the image’s contrast.

You might be using the same ink and the same coverage, but offset inks are transparent, thus allowing the paper they are printed on to “bloom through.” This is not a problem when printing on a white stock, but the darker the paper, the more it will influence the colors printed on it.

Be prepared. While you should always take a look at samples of similar projects on similar stock, they are no indication how your files will print when on press.

Drawdowns

“A drawdown is a great way to see how inks look on a specific stock,” says Allen Strohmeier, principal of Allen Strohmeier Prints in Half Moon Bay, Calif. “Larger printers offer this service in-house; a smaller print shop can get samples from their ink supplier.”

Drawdowns are great for solids, but do not allow you to judge how a full-color image, or any screened image for that matter, will look on the sheet.

Piggyback

If it’s a CMYK job on a light colored stock, ask your printer to run a few sheets of your chosen paper at the end of another print run. When going this route, keep in mind that it takes 50 to 100 sheets of the stock in question to give you a good evaluation.

Most importantly, the images of the original press run naturally have not been adjusted to allow for your paper’s hue (i.e., printing on a cream or ivory colored sheet will give your CMYK a warmer tint). To allow skin tones to appear as natural as possible, yellow should be subtracted from the image’s midtones to compensate for the stock color.

And don’t forget timing. You have to wait until your printer actually runs a similar job with the same sheet size as yours to allow you an educated or fair evaluation.

So what do you do if you don’t have the time to spare?

If you can’t wait to test your stock at the end of another print run (a similar ink coverage with the same sheet sizes might not be scheduled for another week or two), consider getting a one-off print from a digital press like the Indigo (the digital press closest to offset) on your stock. This is not a perfect match, but gives you a good indication of what you can expect on the actual press run.

The Under-Printing Solution

If your project includes full-color images on a medium to dark stock, under-printing a white opaque ink will help you keep the colors vibrant.

White inks, as well as all metallic inks, are by nature opaque and allow offset inks to sit on top of them – literally. Two or three hits of white or silver ink give you the best support for your images.

Wet-trapping. For a subtle look, run the opaque inks in line with your CMYK – not preferred.

Dry-trapping. Waiting for the opaque inks to dry before running the CMYK inks allows for maximum “pop” or contrast of your images – most preferred.

UV-inks. Another option is to use UV inks, which are dried on the run between each print cylinder, but not every printer has the equipment. (Other than time, there might not be any overall savings in comparison to dry-trapping.)

On light to medium colored stocks

If under-printing is not an option for you and you are printing on a light or medium colored stock, add a small percentage of silver ink to one of your colors. It will enhance the opacity of this specific color and give your images more hold…although silver will add a slightly graying effect to your color.

Amazing effects

My personal favorites, when it comes to printing on uncoated colored stocks, are the special effects that are possible in combination with a tactile experience when holding the piece.

Colored stocks can make a one-color job look stunning. Any metallic ink (or white opaque) is ideal for printing on dark papers, but silver is the most effective because of its inherent reflectivity. Just remember, two hits give the best coverage.

Printing opaques only in specific areas to highlight aspects of your image will create an astonishing effect … and make your clients notice.

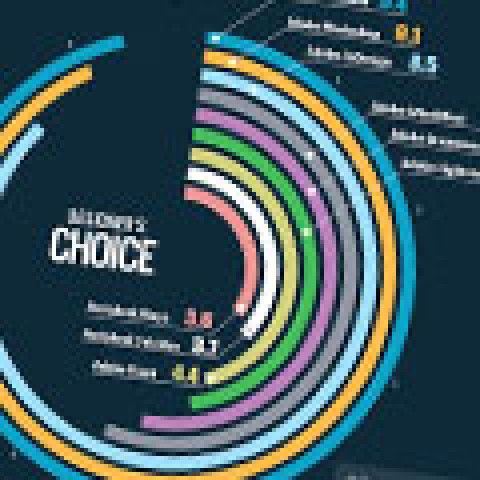

Or create art for its own sake by selecting the one channel of your CMYK image that gives the most desirable effect and print it as a solid, or posterization, or reverse or … the possibilities are endless.

“The key, as with any print job, is to get your vision of the project in line with what is possible with pre-press and on press,” Strohmeier says. “Choose a printer that has experience with the kind of effect you want to achieve and that believes in your project as much as you do.”

———-