The topic of using recycled fiber in printing papers is being discussed more actively within the Two Sides network these days due to the notion that “more recycled content in printing papers is better for the environment”.

I would add: “it depends on the situation.” I say this because generalizing about the benefits of recycled fiber use can be misleading due to the many environmental and economic factors at play in the life cycle of paper products. In other words, wood-based paper grades can be equally, or even more, sustainable if they are being produced responsibly.

We do need to talk about sustainability in this case because buying paper to make printed products involves both economic and environmental considerations.

Recovering and recycling paper products is a good thing. It reduces waste to landfills and extends the use of a valuable raw material. In turn, recovered paper should be re-used as a raw material in products in the most sustainable way possible. That may or may not include high-end printing papers (e.g., catalogs and magazines).

There are industry arguments on both sides of the coin. Many say that one of the most sustainable ways to use recovered paper is in lower quality grades of paper (carton board, paperboard, etc.) where less processing and no de-inking is needed. This typically also means less cost and less environmental concerns. Others point out that high quality recovered paper (if available) should be re-used to make printing papers due to its high content of long (Kraft) fibers. In either situation, the right conditions must be in place to make it environmentally and economically sustainable.

The environmental footprint of a grade of printing paper depends entirely on its specific life cycle, including forestry practices, environmental performance of pulp and paper mills and suppliers, transportation, the list goes on.

In our industry, many of the environmental indicators associated with this life cycle are measured and reported in terms of emissions to air, water, soil and solid waste to landfill, among many others. For companies committed to sustainability, tracking these indicators and improving performance is a key method used to reduce the overall environmental footprint of their paper products.

The environmental performance of the pulp and paper industry varies widely between countries, between companies and between manufacturing facilities. This is because environmental performance depends on the use of the best available technology and the commitment to sustainability of a given company or facility.

Each product life cycle is also associated with other elements such as forest biodiversity and the ecosystem services of a well-managed forest (water filtration, air purification and carbon sequestration), recreational benefits, jobs created and community spin-offs from forestry and manufacturing, the cost of de-inked pulp, paper quality considerations, the distance needed to transport recovered paper and de-inked pulp for processing, and more.

Although Life-cycle Assessment (LCA) studies can be useful tools to help understand the environmental footprint of paper products, they have limitations and they cannot consider many of the environmental and economic considerations listed above. Results should be communicated with caution across product categories and they should not be seen as an indication of overall “sustainability”.

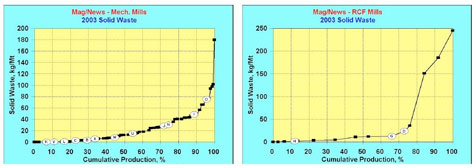

The two graphs below show the variability in solid waste generation from two different types of integrated printing paper mills: ones using wood-based mechanical pulp (left) and ones using de-inked pulp (right). Each data point (squares and circles) represents a pulp and paper mill site.

The range, from low to high, is similar in both cases and it is very likely to have an integrated mechanical pulp and paper mill site with better performance than an integrated recycled mill site. Based on industry benchmarking studies I have participated in, the same is true for other environmental indicators as well.

Another example would be an increased carbon footprint of an office paper grade due to switching from a low-carbon Kraft pulp supply to a de-inked recycled pulp supplier that relies heavily on fossil fuels. Kraft pulp can have a relatively low carbon footprint due to low reliance on fossil fuels and use of renewable, carbon-neutral energy (biomass and black liquor). Sappi’s most recent eQ Journal, Rethinking Recycling, also discusses this topic.

The above examples illustrate the potential risks of generalizing the benefits of using recycled fiber without looking into the environmental performance of specific paper products and manufacturers. For certain grades of paper, it can lead to overstating the environmental benefits of one raw material (recycled fiber) over another (wood fiber), and this appears to contravene the U.S. Federal Trade Commission Green Guides.

Ultimately, wood-based paper grades can have a lower environmental footprint than grades containing recycled content just because of the specific situation and life cycle that surrounds each paper grade, and vice-versa. One can also be more economical to produce than the other depending on the situation, such as proximity and cost of fiber. Recycled fiber and wood fiber from well-managed forests can be equally sustainable raw materials for papermaking.

If we want to evaluate environmental performance, we should be spending less time debating which fiber type to use and more time measuring real product-specific environmental performance indicators. Several tools, such as environmental scorecards and declarations, are available to collect specific data on companies, mill sites and paper grades (e.g., Environmental Paper Assessment Tool, Paper Profile, WWF Paper Scorecard or customized scorecards).

—————————-