NOT A PRO MEMBER YET?

As a graphic designer you deserve access to the latest swatchbooks and insights for print design.

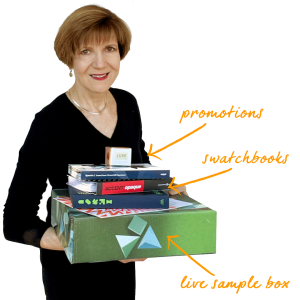

PRO Members get exclusive resources, swatchbooks from 60+ mills, expert insights and so much more. Together, we’ll take your print projects to new heights and WOW your clients!

Join our waitlist now and be the first to know when we open for new members.